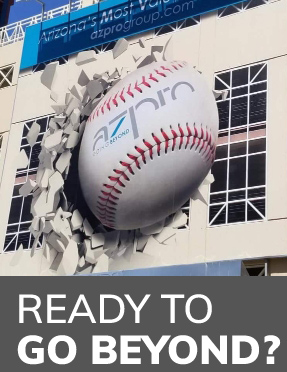

By Conner Carpenter Often wonder just how an award-winning large graphics company operates and what processes are in place to achieve excellence in the industry? Clients are often drawn to azpro mainly because our  proven formula allows us to provide top-of-the-line large format graphics, especially when it comes to our niche business of retail signage, corporate environments, and vehicle fleet wraps. We deliver on the promise of producing concepts and products that exceed our clients’ expectations, and below is the process we follow on a daily basis.

proven formula allows us to provide top-of-the-line large format graphics, especially when it comes to our niche business of retail signage, corporate environments, and vehicle fleet wraps. We deliver on the promise of producing concepts and products that exceed our clients’ expectations, and below is the process we follow on a daily basis.

SALES TO DESIGN

Once our motivated sales team secures an order, the conceptual design team collaborates with them and the client to create a visual campaign based on the messages, products, and services our clients want to promote.

Once our motivated sales team secures an order, the conceptual design team collaborates with them and the client to create a visual campaign based on the messages, products, and services our clients want to promote. DESIGN TO PRINT

After our team completes the design, we send it back to the client for any necessary adjustments. The client then approves the design, thus beginning the formatting process for digital printing. The two featured machines in our arsenal of seven large format printers are the flatbed Hewlett-Packard FB11000 and the VUTEk HS125. These machines offer detailed color reproduction and expanded gamut. While being 3M MCS (Warranty Qualified Manufacturer) and Avery Dennison ICS (Warranty Guarantee) certified, their increased print and cut accuracy produces at a total of 6,400 sq.ft./hr, accounting for half of the entire shop’s capabilities. We use this cutting-edge technology to maximize material usage and cost savings for our clients. In order to produce quality products, we invested in Caldera which is large printing software that allows us to support high-quality, wide-format imaging, with a commitment to increasing productivity, cost-efficiency, and color output.

expanded gamut. While being 3M MCS (Warranty Qualified Manufacturer) and Avery Dennison ICS (Warranty Guarantee) certified, their increased print and cut accuracy produces at a total of 6,400 sq.ft./hr, accounting for half of the entire shop’s capabilities. We use this cutting-edge technology to maximize material usage and cost savings for our clients. In order to produce quality products, we invested in Caldera which is large printing software that allows us to support high-quality, wide-format imaging, with a commitment to increasing productivity, cost-efficiency, and color output. PRINT TO PRODUCTION

Once the printing process is complete, our print teams transition the products to the final stages of development. The next step in this process is cutting for the purposes of kitting. Our two state-of-the-art Zund digital cutting machines give us the opportunity to create a collection of multiple designs to morph into one amazing design campaign.PRODUCTION TO INSTALL

After the product is precisely and carefully cut, the production team looks over the product for quality control. The team verifies the image and quantity needed to fulfill the order. The instant the products pass our quality check they are packaged with care and shipped to our clients. Our 3M Certified install team is second to none, providing quality installation services for retail signage, corporate décor, and vehicle fleet wraps. ]]>